Contents:

- 2.1: Setting Up the Equipment Maintenance

Module

- 2.1.1: Equipment Names

- 2.1.2: Equipment Classifications

- 2.1.3: Maintenance Types

- 2.1.4: Materials for Equipment

Maintenance

- 2.1.5: Replacement Parts for Equipment

Maintenance

- 2.1.6: Equipment Maintenance Operations

- 2.1.7: Equipment Maintenance Profiles

2.1 Setting Up the Equipment Maintenance Module

|

|

Before you start using the equipment maintenance module in

EZM Web to track and control maintenance for your equipment, you must set it

up. To start setting up the equipment

maintenance module, click on Setup under the Equipment Maintenance drop-down

list on the left side of the screen:

![]()

Fig. 2.1 – Setup Link

After you click on Setup, you will be taken to the

following screen, which we’ll call the “equipment maintenance module setup

screen”:

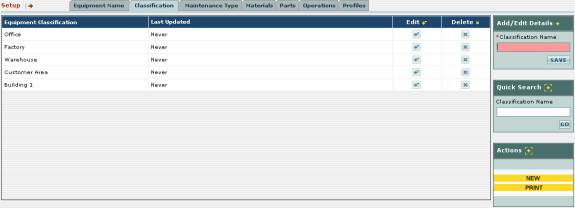

Fig. 2.2 – Equipment maintenance module setup screen showing

multiple tabs along the top

In this section of EZM Web, you set up the equipment

maintenance module. Notice that at the

top part of the screen there are several tabs: Equipment Name, Classification,

Maintenance Type, Materials, Parts, Operations, and

Profiles:

![]()

Fig. 2.3 – Tabs showing sections of equipment maintenance

module setup

These

tabs represent different areas of the equipment maintenance module setup. Clicking on each tab will bring you to the

corresponding area of the setup section.

Here is a brief description of each of the areas:

o

Equipment Name: Here

you enter names / short descriptions of types of equipment that you enter into

EZM Web. Every time you enter a piece

of equipment into EZM Web, you assign it one of the equipment names you have

entered here. This is to help you

identify, at a glance, what the various types of equipment you have entered

into EZM Web.

o

Classification: EZM Web

also lets you assign pieces of equipment different equipment

classifications. This allows you to group

related pieces of equipment together, all sharing the same classification, for

maintenance tracking purposes. Clicking

on the Classification tab takes you to a section of EZM Web where you

enter the names of the equipment classifications you want to create.

o

Maintenance Type: This is

where you enter names / short descriptions of maintenance events that you

schedule for your equipment in EZM Web.

Every periodic or emergency maintenance event that you create in EZM Web

is assigned one of the names that you enter here.

o

Materials: This is where you enter

the materials that you use in your equipment maintenance.

o

Parts: This is where you enter the

replacement parts that you use in your equipment maintenance.

o

Operations: In EZM Web, each

maintenance event that you schedule for a piece of equipment breaks down into

individual operations. Each of these

operations must have a name chosen from a list you enter into the section of

EZM Web accessed by clicking on the Operations tab.

o

Profiles: In EZM Web, a Maintenance

Profile is a complete description of a maintenance schedule. By clicking on the Profiles tab, you

are taken to a section of EZM Web where you can create new or edit Maintenance

Profiles. Thus, whenever you input a

new piece of equipment into EZM Web, you must select one of the maintenance profiles

you’ve created. This is advantageous

because you need not input every detail of the maintenance schedule for every

piece of equipment you enter, but rather just select the maintenance profile

that contains the maintenance you want to have performed for that

equipment. This saves a lot of time

when entering several pieces of equipment which all have the same maintenance

requirements.

All of

the sections mentioned above are explained in depth in the following sections.

2.1.1

Equipment Names

As

mentioned in section 2.1 Setting Up the Equipment Maintenance Module,

the equipment maintenance module setup section of EZM Web includes a section

where you enter Equipment Names, which are names / short descriptions of types

of equipment that you enter into EZM Web.

Every time you enter a piece of equipment into EZM Web, you assign it

one of the equipment names you have entered.

This is to help you identify, at a glance, what the various types of

equipment you have entered into the EZM Web are.

To get to

the section of EZM Web where you enter Equipment Names, first you need to go to

the equipment maintenance module setup screen. Click on the Equipment Name

tab (the leftmost tab) at the top of the screen:

![]()

Fig 2.4 - Equipment Name tab

Doing this will take you to the section of the equipment

module setup where you can enter the Equipment Names:

Fig 2.5 – Section of equipment maintenance module setup

for equipment names

All of the equipment names you have already entered will

be listed in this screen:

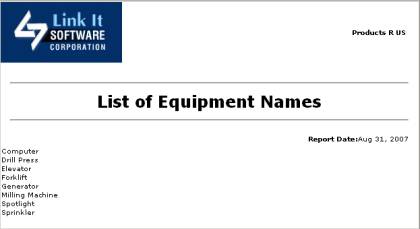

Fig 2.6 – List of all equipment names

In this section of EZM Web, you can:

o

Enter new equipment names

o

Edit an existing equipment name

o

Delete an equipment name

o

Print a report showing all of the equipment names you’ve

entered

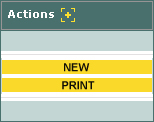

Entering a New Equipment Name

To enter a new equipment name, first locate the

yellow-colored NEW button at the bottom right part of the screen:

Fig 2.7 – “NEW” button for entering a new equipment name

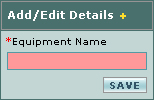

Click on

the NEW button to enter a new equipment name. Notice that the Add / Edit Details box in the upper right

part of the screen contains a box called Equipment Name that turns a

salmon color after you’ve clicked on the NEW button:

Fig 2.8 – “Add / Edit Details” box where you enter a new

equipment name

Next, click in the salmon-colored box and type the new

equipment name. Then click on the SAVE

button. The new equipment name which

you typed will appear in the list.

Editing an Existing Equipment Name

To edit an existing equipment name, first locate the

equipment name in the list and then look to the right of it until you encounter

a ![]() button under the Edit column:

button under the Edit column:

Fig 2.9 – “Edit” column with edit buttons

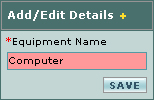

Click on the ![]() button. Notice that the Add

/ Edit Details box contains a box called Equipment Name turns a

salmon color after you’ve clicked on the NEW button and fills in with

the equipment name you want to edit (which in the case of fig. 2.10 is

“computer”):

button. Notice that the Add

/ Edit Details box contains a box called Equipment Name turns a

salmon color after you’ve clicked on the NEW button and fills in with

the equipment name you want to edit (which in the case of fig. 2.10 is

“computer”):

Fig 2.10 - “Add / Edit Details” box; editing an equipment

name

Click in the salmon-colored box and type to make the

desired changes to the equipment name.

Then click on the SAVE button.

The updated equipment name will be shown in the list.

Deleting an Equipment

Name

To delete an existing equipment name, first locate the equipment

name in the list and then look to the right of it until you encounter a ![]() button under the Delete column:

button under the Delete column:

Fig 2.11 – “Delete” column with delete buttons

Click on

the ![]() button. The equipment

name to the left of the delete button you clicked will be deleted from the

list.

button. The equipment

name to the left of the delete button you clicked will be deleted from the

list.

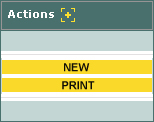

Printing a List of All Equipment Names

To print

a list of all equipment names entered into EZM Web so far, first locate the

yellow-colored PRINT button at the bottom right part of the screen:

Fig 2.12 – “PRINT” button for printing the list of

equipment names

Clicking on the PRINT button will print the

following report:

Fig 2.13 – Report showing list of all equipment names

2.1.2 Equipment Classifications

As

mentioned in section 2.1 Setting Up the

Equipment Maintenance Module, the equipment maintenance module setup

section of EZM Web includes a section where you enter Equipment

Classifications, which are names of groups which you can assign different

pieces of equipment to for maintenance tracking purposes. Every time you enter a piece of equipment

into EZM Web, you assign it one of the Classification names you have

entered.

To get to

the section of EZM Web where you enter Equipment Classifications, first you

need to go to the equipment maintenance module setup screen

Click on the Classification tab at the top of the screen:

![]()

Fig 2.14 - Classification tab

Doing this will take you to the section of the equipment

module setup where you can enter the Equipment classifications:

Fig 2.15 – Section of equipment maintenance module setup

for equipment classifications

All of the Equipment classifications you have already

entered will be listed in this screen:

Fig 2.16 – List of all equipment classifications

In this section of EZM Web, you can:

o

Enter new equipment classifications

o

Edit an existing equipment classification

o

Delete an equipment classification

o

Print a report showing all of the equipment

classifications you’ve entered

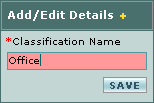

Entering a New Equipment Classification

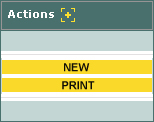

To enter a new equipment classification, first locate the

yellow-colored NEW button at the bottom right part of the screen:

Fig 2.17 – “NEW” button for entering a new equipment name

Click on

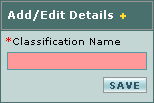

the NEW button to enter a new classification. Notice that the Add / Edit Details box in the upper right

part of the screen contains a box called Classification Name that turns

a salmon color after you’ve clicked on the NEW button:

Fig 2.18 – “Add / Edit Details” box where you enter a new

classification

Next, click in the salmon-colored box and type the new

classification. Then click on the SAVE

button. The new classification which

you typed will appear in the list.

Editing an Existing Equipment

Classification

To edit an existing equipment classification, first locate

the classification in the list and then look to the right of it until you

encounter a ![]() button under the Edit column:

button under the Edit column:

Fig 2.19 – “Edit” column with edit buttons

Click on the ![]() button. Notice that the Add

/ Edit Details box contains a box called Classification turns a

salmon color after you’ve clicked on the NEW button and fills in with

the classification you want to edit (which in the case of fig. 2.20 is

“Office”):

button. Notice that the Add

/ Edit Details box contains a box called Classification turns a

salmon color after you’ve clicked on the NEW button and fills in with

the classification you want to edit (which in the case of fig. 2.20 is

“Office”):

Fig 2.20 - “Add / Edit Details” box; editing an equipment

name

Click in the salmon-colored box and type to make the

desired changes to the classification.

Then click on the SAVE button.

The updated classification will be shown in the list.

Deleting an Equipment Classification

To delete an existing classification, first locate the

classification in the list and then look to the right of it until you encounter

a ![]() button under the Delete column:

button under the Delete column:

Fig 2.21 – “Delete” column with delete buttons

Click on

the ![]() button. The

classification to the left of the delete button you clicked will be deleted

from the list.

button. The

classification to the left of the delete button you clicked will be deleted

from the list.

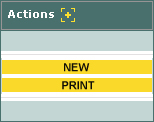

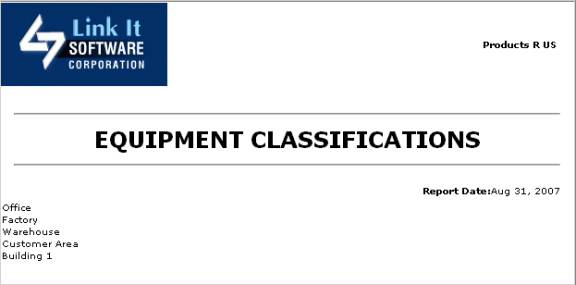

Printing a List of All Equipment Classifications

To print

a list of all equipment classifications entered into EZM Web so far, first

locate the yellow-colored PRINT button at the bottom right part of the

screen:

Fig 2.23 – “PRINT” button for printing the list of

equipment classifications

Clicking on the PRINT button will print the following

report:

Fig 2.24 – Report showing list of all equipment

classifications

2.1.3 Maintenance Types

As

mentioned in section 2.1 Setting Up the

Equipment Maintenance Module, the equipment maintenance module setup

section of EZM Web includes a section where you enter Maintenance Types, which

are names / short descriptions of maintenance events that you schedule for your

equipment in EZM Web. Every periodic or

emergency maintenance event that you create in EZM Web is assigned one of the

names that you enter here.

To get to

the section of EZM Web where you enter Maintenance Types, first you need to go

to the equipment maintenance module setup screen (see section 2.1 Setting Up the Equipment Maintenance

Module for how to get here).

Click on the Maintenance Type tab at the top of the screen:

![]()

Fig 2.25 – Maintenance Type tab

Doing

this will take you to the section of the equipment module setup where you can

enter the Maintenance Types:

Fig 2.26 – Section of equipment maintenance module setup

for maintenance types

All of the maintenance types you have already entered will

be listed in this screen:

Fig 2.27 – List of maintenance types

In this section of EZM Web, you can:

o

Enter new maintenance types

o

Edit an existing maintenance type

o

Delete a maintenance type

o

Print a report showing all of the maintenance types you’ve

entered

Entering a New

Maintenance Type

To enter a new maintenance type, first locate the

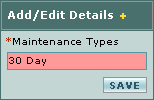

yellow-colored NEW button at the bottom right part of the screen:

Fig 2.28 – “NEW” button for entering new maintenance types

Click on

the NEW button to enter a new maintenance type. Notice that the Add / Edit Details

box in the upper right part of the screen contains a box called Maintenance

Type that turns a salmon color after you’ve clicked on the NEW

button:

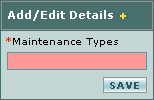

Fig 2.29 – “Add / Edit Details” box where you enter a new

maintenance type

Next, click in the salmon-colored box and type the new

maintenance type. Then click on the SAVE

button. The new maintenance type which

you typed will appear in the list.

Editing an Existing Maintenance Type

To edit an existing maintenance type, first locate the

maintenance type in the list and then look to the right of it until you

encounter a ![]() button under the Edit column:

button under the Edit column:

Fig 2.30 – “Edit” column with edit buttons

Click on the ![]() button. Notice that the Add

/ Edit Details box contains a box called Maintenance Type turns a

salmon color after you’ve clicked on the NEW button and fills in with

the maintenance type you want to edit (which in the case of fig. 2.31 is “30

Day”):

button. Notice that the Add

/ Edit Details box contains a box called Maintenance Type turns a

salmon color after you’ve clicked on the NEW button and fills in with

the maintenance type you want to edit (which in the case of fig. 2.31 is “30

Day”):

Fig 2.31 - “Add / Edit Details” box; editing a maintenance

type

Click in the salmon-colored box and type to make the

desired changes to the maintenance type.

Then click on the SAVE button.

The updated maintenance type will be shown in the list.

Deleting a Maintenance Type

To delete an existing maintenance type, first locate the

maintenance type in the list and then look to the right of it until you

encounter a ![]() button under the Delete column:

button under the Delete column:

Fig 2.32 – “Delete” column with delete buttons

Click on

the ![]() button. The maintenance

type to the left of the delete button you clicked will be deleted from the

list.

button. The maintenance

type to the left of the delete button you clicked will be deleted from the

list.

Printing a List of All Maintenance Types

To print

a list of all maintenance types entered into EZM Web so far, first locate the

yellow-colored PRINT button at the bottom right part of the screen:

Fig 2.33 – “PRINT” button for printing the list of

maintenance types

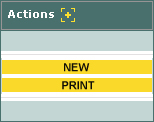

Clicking on the PRINT button will print the

following report:

Fig 2.34 – Report showing list of all maintenance types

2.1.4

Materials for Equipment Maintenance

As

mentioned in section 2.1 Setting Up the

Equipment Maintenance Module, the equipment maintenance module setup

section of EZM Web includes a section where you enter the materials that you

use in your equipment maintenance.

To get to

the section of EZM Web where you enter materials for equipment maintenance,

first you need to go to the equipment maintenance module setup screen (see

section 2.1 Setting Up the Equipment

Maintenance Module for how to get here). Click on the Materials tab at the top of the screen:

![]()

Fig 2.35 – Materials tab

Doing

this will take you to the section of the equipment module setup where you can

enter the materials you will be using in equipment maintenance:

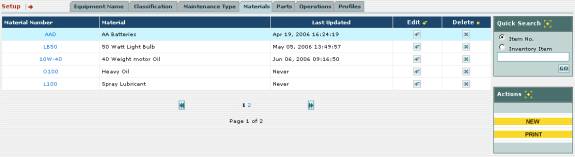

Fig 2.36 – Section of equipment maintenance module setup

for equipment maintenance materials

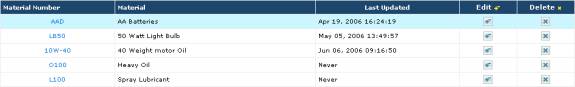

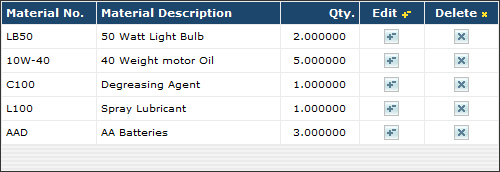

In the

screen shown in fig. 2.36, you will see all of the materials for equipment

maintenance which you have entered into EZM Web so far:

Fig 2.37 – List of materials for equipment maintenance

This list not only includes items you’ve entered here, but

also inventory items you’ve entered into EZM Web through the Inventory module

which you’ve designated as being materials used in equipment maintenance. (See section 4.1.2 Inputting Your Inventory Items

for additional information on inputting items through the Inventory module).

In this section of EZM Web, you can:

o

Enter new materials for equipment maintenance

o

Edit existing materials

o

Delete materials

o

Print a report showing all of the materials for equipment

maintenance you’ve entered

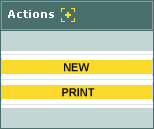

Entering a New Material

To enter a new material, first locate the yellow-colored NEW

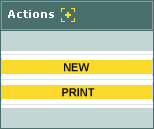

button at the bottom right part of the screen:

Fig 2.38 – “NEW” button for entering a new material

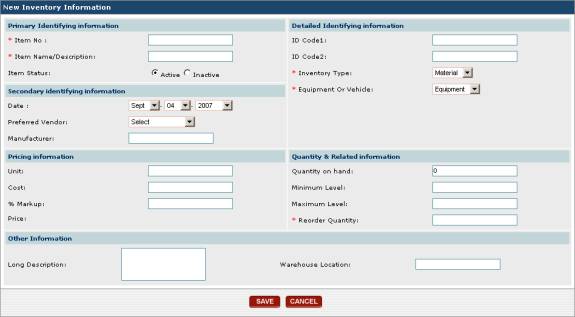

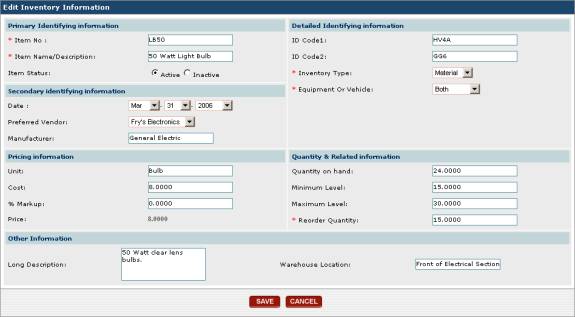

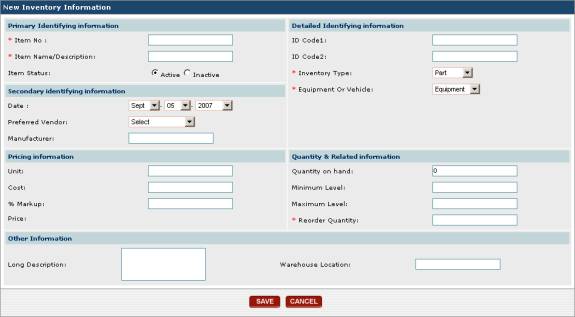

After clicking on the NEW button, a screen will open where you can enter the details

about the new material:

Fig 2.39 – Screen for entering information about new

material

Notice that Inventory Type and Equipment or

Vehicle have been automatically given the values “Material” and “Equipment”

respectively to indicate that the new inventory item you are entering is a

material used in equipment maintenance.

You can change these values, but, if you do, the item you enter will not

appear in the list of materials for equipment maintenance as seen in figs. 2.36

and 2.37 or be available for inclusion in equipment maintenance.

For detailed information on the purpose of each data entry

field in this screen, please consult section 4.1.2 Entering Your Inventory Items.

When you have finished entering all of the information in

this screen, click on the SAVE button to enter the new material into EZM

Web. If you have changed your mind and

no longer want to enter the new material, click on the CANCEL button to

return to the list of materials without entering anything. The SAVE and CANCEL buttons

are at the bottom of the screen:

![]()

Fig 2.40 – Close-up of fig. 2.39 showing “SAVE” and

“CANCEL” buttons

Editing an Existing

Material

To edit an existing material, first locate the material in

the list of materials for equipment maintenance (as shown in figs. 2.36 and

2.37) and then look to the right of it until you encounter a ![]() button under the Edit column:

button under the Edit column:

Fig 2.41 – “Edit” column with edit buttons

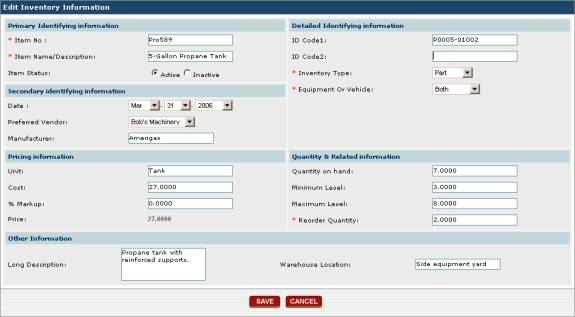

Clicking on the ![]() button will bring up the following screen where you can edit the

material:

button will bring up the following screen where you can edit the

material:

Fig 2.42 – Screen for entering information about new

material

This

screen is similar to the one where you enter a new material (see fig.

2.39). However, notice that all of the

existing information for the material you are editing is filled in the data

fields. You may change any of the data

fields in this screen.

For

detailed information on the purpose of each data entry field in this screen,

please consult section 4.1.2 Entering

Your Inventory Items.

When you

have finished making all of your desired changes, click on the SAVE

button to save the changes to the material.

If you have changed your mind and no longer want to make any changes,

click on the CANCEL button to return to the list of materials without

changing anything. The SAVE and CANCEL

buttons are at the bottom of the screen:

![]()

Fig 2.43 – Close-up of fig. 2.39 showing “SAVE” and

“CANCEL” buttons

Deleting a Material

To edit an existing material, first locate the maintenance

type in the list and then look to the right of it until you encounter a ![]() button under the Delete column:

button under the Delete column:

Fig 2.44 – “Delete” column with delete buttons

Click on

the ![]() button. The material to

the left of the delete button you clicked will be deleted from the list.

button. The material to

the left of the delete button you clicked will be deleted from the list.

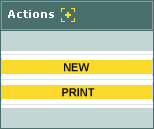

Printing a List of Materials Used in Equipment

Maintenance

To print

a list of all materials for equipment maintenance entered into EZM Web so far,

first locate the yellow-colored PRINT button at the bottom right part of

the screen:

Fig 2.45 – “PRINT” button for printing list of materials

Clicking

on the PRINT button will print the following report:

Fig 2.46 – Report showing list of all materials used in

equipment maintenance

2.1.5

Replacement Parts for Equipment Maintenance

As

mentioned in section 2.1 Setting Up the

Equipment Maintenance Module, the equipment maintenance module setup

section of EZM Web includes a section where you enter

the replacement parts that you use in your equipment maintenance. Replacement parts are items you include in

your maintenance events which need to be replaced in the event that there is a

part failure or that part fails an inspection.

To get to the section of EZM Web where you

enter replacement parts for equipment maintenance, first you need to go to

the equipment maintenance module setup screen (see section 2.1 Setting Up the Equipment Maintenance Module

for how to get here). Click on the Parts

tab at the top of the screen:

![]()

Fig 2.46 – Parts tab

Doing

this will take you to the section of the equipment module setup where you can

enter the replacement parts you will be using in equipment maintenance:

Fig 2.47 – Section of equipment maintenance module setup

for equipment maintenance replacement parts

In the

screen shown in fig. 2.46, you will see all of the replacement parts for

equipment maintenance which you have entered into EZM Web so far:

Fig 2.48 – List of replacement parts for equipment

maintenance

This list not only includes items you’ve entered here, but

also inventory items you’ve entered into the EZM Web through the Inventory

module which you’ve designated as being replacement parts used in equipment

maintenance. (See section 4.1.2 Inputting Your Inventory Items

for additional information on inputting items through the Inventory module).

In this section of the EZM Web, you can:

o

Enter new replacement parts for equipment maintenance

o

Edit existing replacement parts

o

Delete replacement parts

o

Print a report showing all of the replacement parts for

equipment maintenance you’ve entered

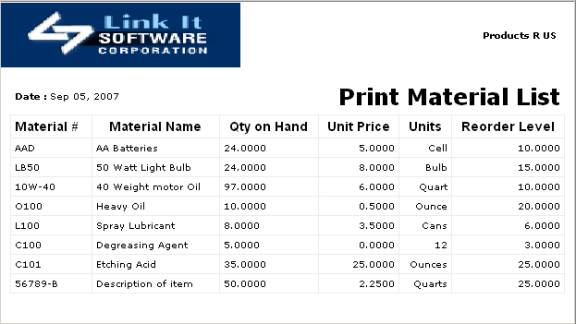

Entering a New Replacement Part

To enter a new replacement part, first locate the

yellow-colored NEW button at the bottom right part of the screen:

Fig 2.49 – “NEW” button for entering a new material

After clicking on the NEW button, a screen will open where you can enter the details

about the new replacement part:

Fig 2.50 – Screen for entering information about new

replacement part

Notice that Inventory Type and Equipment or

Vehicle have been automatically given the values “Part” and “Equipment”

respectively to indicate that the new inventory item you are entering is a

replacement part used in equipment maintenance. You can change these values, but, if you do, the item you enter

will not appear in the list of replacement parts for equipment maintenance or

be available for inclusion in equipment maintenance.

For detailed information on the purpose of each data entry

field in this screen, please consult section 4.1.2 Entering Your Inventory Items.

When you have finished entering all of the information in

this screen, click on the SAVE button to enter the new replacement part

into EZM Web. If you have changed your

mind and no longer want to enter the new replacement part, click on the CANCEL

button to return to the list of parts without entering anything. The SAVE and CANCEL buttons

are at the bottom of the screen:

![]()

Fig 2.51 – Close-up of fig. 2.49 showing “SAVE” and

“CANCEL” buttons

Editing an Existing

Replacement Part

To edit an existing replacement part, first locate the

part in the list of replacement parts for equipment maintenance (as shown in

figs. 2.36 and 2.37) and then look to the right of it until you encounter

a ![]() button under the Edit column:

button under the Edit column:

Fig 2.52 – “Edit” column with edit buttons

Clicking on the ![]() button will bring up the following screen where you can edit the

replacement part:

button will bring up the following screen where you can edit the

replacement part:

Fig 2.53 – Screen for entering information about new

material

This

screen is similar to the one where you enter a new replacement part (see fig.

2.39). However, notice that all of the

existing information for the part you are editing is filled in the data

fields. You may change any of the data

fields in this screen.

For

detailed information on the purpose of each data entry field in this screen,

please consult section 4.1.2 Entering

Your Inventory Items.

When you

have finished making all of your desired changes, click on the SAVE

button to save the changes to the part.

If you have changed your mind and no longer want to make any changes,

click on the CANCEL button to return to the list of replacement parts

without changing anything. The SAVE

and CANCEL buttons are at the bottom of the screen:

![]()

Fig 2.54 – Close-up of fig. 2.39 showing “SAVE” and

“CANCEL” buttons

Deleting a Replacement Part

To edit an existing replacement part, first locate the

maintenance type in the list and then look to the right of it until you

encounter a ![]() button under the Delete column:

button under the Delete column:

Fig 2.55 – “Delete” column with delete buttons

Click on

the ![]() button. The replacement

part to the left of the delete button you clicked will be deleted from the

list.

button. The replacement

part to the left of the delete button you clicked will be deleted from the

list.

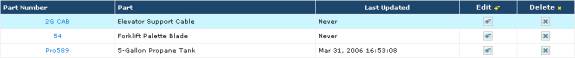

Printing a List of Replacement Parts Used in

Equipment Maintenance

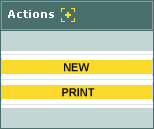

To print

a list of all replacement parts used in equipment maintenance entered into EZM

Web so far, first locate the yellow-colored PRINT button at the bottom

right part of the screen:

Fig 2.56 – “PRINT” button for printing list of replacement

parts

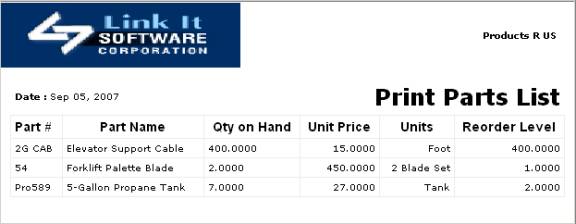

Clicking

on the PRINT button will print the following report:

Fig 2.57 – Report showing list of all replacement parts

used in equipment maintenance

2.1.6 Equipment Maintenance Operations

As

mentioned in section 2.1 Setting Up the

Equipment Maintenance Module, the equipment maintenance module setup

section of EZM Web includes a section where you enter the operations that you

perform in equipment maintenance. In

EZM Web, each maintenance event that you schedule for a piece of equipment

breaks down into individual operations.

Each of these operations must be chosen from a list you enter into this

section of EZM Web.

To get to

the section of EZM Web where you enter Operations, first you need to go to the

equipment maintenance module setup screen (see section 2.1 Setting Up the Equipment Maintenance

Module for how to get here).

Click on the Operations tab at the top of the screen:

![]()

Fig 2.58 – Operations tab

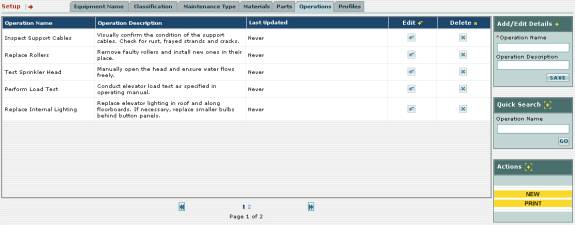

Doing

this will take you to the section of the equipment module setup where you can

enter the operations:

Fig 2.59 – Section of equipment maintenance module setup

for operations

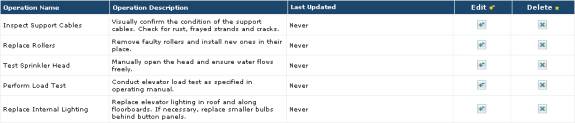

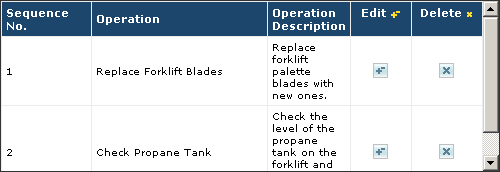

All of the operations you have already entered will be

listed in this screen:

Fig 2.60 – Detail of fig. 2.59 showing list of operations

As you can see, each operation is listed with its name and

a detailed description of what is done to accomplish each operation.

In this section of the EZM Web, you can:

o

Enter new operations

o

Edit existing operations

o

Delete operations

o

Print a report showing all of the operations you’ve

entered

Entering a New Operation

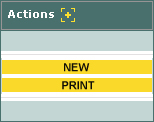

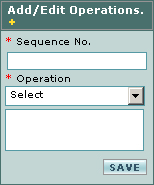

To enter a new operation, first locate the yellow-colored NEW

button at the bottom right part of the screen:

Fig 2.61 – “NEW” button for entering new operations

Click on

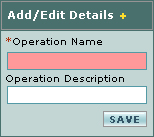

the NEW button to enter a new operation. Notice that the Add / Edit Details box in the upper right

part of the screen contains a box called Operation Name that turns a

salmon color after you’ve clicked on the NEW button:

Fig 2.62 – “Add / Edit Details” box where you enter a new

operation

Click in the Operation Name box and type in the

name of the operation. The name of the

operation should be a short identifying name such as “Inspect Ceiling

Lights”. In addition to entering the

name of the operation, you must also enter a detailed description of the

operation. After you’ve entered the Operation

Name, then click in the Operation Description field just below (also

shown in fig. 2.62) and type in the operation description.

After you’ve entered the name and description of the

operation, then click on the SAVE button. The new operation will appear in the list.

Editing an Existing

Operation

To edit an existing operation, first locate operation in

the list and then look to the right of it until you encounter a ![]() button under the Edit column:

button under the Edit column:

Fig 2.63 – “Edit” column with edit buttons

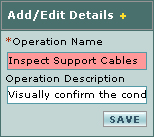

Click on the ![]() button. Notice that the Add

/ Edit Details box contains a box called Operation Name that turns a

salmon color after you’ve clicked on the

button. Notice that the Add

/ Edit Details box contains a box called Operation Name that turns a

salmon color after you’ve clicked on the

![]() button and fills in with the name of the operation you want to

edit (which in the case of fig. 2.64 is “Inspect Support Cables”):

button and fills in with the name of the operation you want to

edit (which in the case of fig. 2.64 is “Inspect Support Cables”):

Fig 2.64 - “Add / Edit Details” box; editing a maintenance

type

Click in the salmon-colored box and type to make the

desired changes to the name of the operation.

You can also edit the description of the operation by clicking in the Operation

Description field and typing to make your changes. When you have finished making your changes

to the operation name and description, then click on the SAVE

button. The updated maintenance type

will be shown in the list.

Deleting an Operation

To delete an existing operation, first locate the

operation in the list and then look to the right of it until you encounter

a ![]() button under the Delete column:

button under the Delete column:

Fig 2.65 – “Delete” column with delete buttons

Click on

the ![]() button. The operation to the left of the delete

button you clicked will be deleted from the list.

button. The operation to the left of the delete

button you clicked will be deleted from the list.

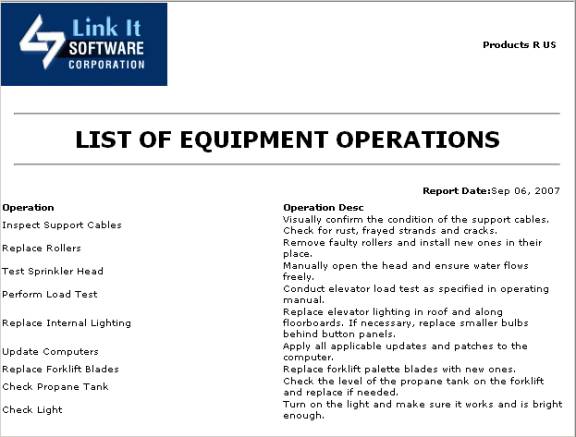

Printing a List of All Operations

To print

a list of all operations entered into EZM Web so far, first locate the

yellow-colored PRINT button at the bottom right part of the screen:

Fig 2.66 – “PRINT” button for printing the list of

maintenance types

Clicking on the PRINT button will print the

following report:

Fig 2.67 – Report showing list of all operations

2.1.7

Equipment Maintenance Profiles

As mentioned

in section 2.1 Setting Up the

Equipment Maintenance Module, the equipment maintenance module setup

section of EZM Web includes a section where you enter maintenance profiles.

Maintenance

profiles are an important part of EZM Web.

A maintenance profile is a complete description of the maintenance for a

piece of equipment. However, a

maintenance profile is not meant for one specific concrete piece of equipment

per se. Rather, it is meant for one or

more pieces of equipment all sharing the same maintenance requirements. The power of maintenance profiles in EZM Web

comes from the fact that when you enter several pieces of equipment into EZM

Web that all have the same maintenance requirements, you only have to apply the

same maintenance profile to each of them when entering them into EZM Web

instead of having to manually enter those maintenance requirements over and

over again for each one.

Each time

you enter a new piece of equipment into EZM Web, you must select the

maintenance profile that contains a description of the maintenance for that

piece of equipment. Therefore, before

you enter any pieces of equipment into EZM Web, you must create at least one

maintenance profile.

As

mentioned before, each maintenance profile is a complete description of the

maintenance requirements for a piece of equipment. A maintenance profile can be decomposed into one or more

maintenance types, which are maintenance actions that are performed

periodically. Furthermore, each

maintenance type can be broken down into the specific steps or operations

needed to complete the maintenance, the materials that are performed in the

maintenance, and the replacement parts that might be needed.

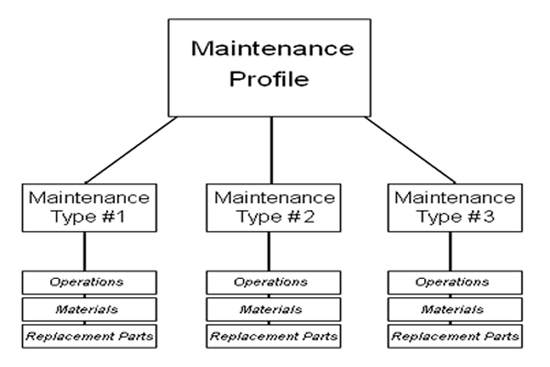

A

graphical representation of the structure of a maintenance profile is shown

below in fig. 2.68:

Fig 2.68 – Graphical representation of the structure of a

maintenance profile

To get to

the section of EZM Web where you enter materials for equipment maintenance,

first you need to go to the equipment maintenance module setup screen (see

section 2.1 Setting Up the Equipment

Maintenance Module for how to get here). Click on the Profiles tab at the top of the screen:

![]()

Fig 2.69 – Profiles Tab

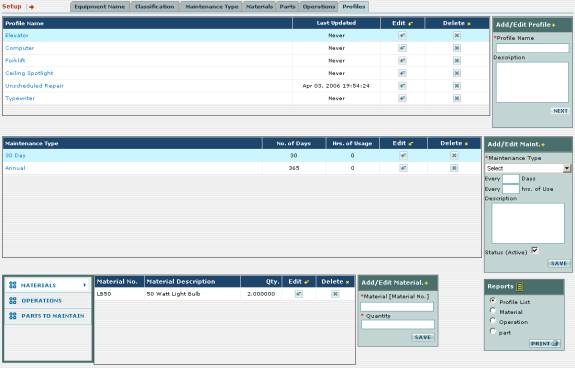

Clicking

on the Profiles tab will take you to the screen where you can enter

equipment maintenance profiles into EZM Web:

Fig 2.69 – Screen for entering equipment maintenance

profiles into EZM Web

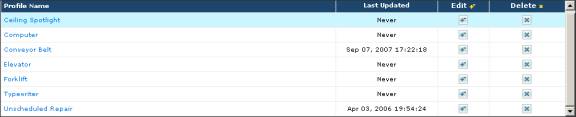

The list

of maintenance profiles which you’ve entered so far is at the top of the

screen:

Fig 2.70 – List of equipment maintenance profiles in EZM

Web

In this

section of the manual, we will describe:

o

How to create a maintenance profile

o

How to add additional maintenance types to a profile

o

How to specify the specific steps to take to complete a

maintenance type (called “operations”)

o

How to specify the materials used in a maintenance type

o

How to specify the replacement parts that might be needed

in maintenance type

o

How to edit maintenance profiles

o

How to print a list of maintenance profiles you’ve entered

into EZM Web

Creating a New Maintenance Profile

To start

creating a new maintenance profile, first look to the upper right part of the

screen for an Add/Edit Profile box:

Fig 2.71 – “Add/Edit Profile” box with “Profile Name” and

“Description” fields

First click in the Profile Name field and type in

the name you wish to refer to this profile throughout EZM Web. You can also click in the Description field

and enter a description of the maintenance that this profile will specify,

although this is optional, and you may leave this field blank if you wish. After you have entered the Profile Name

and (optionally) Description, then click on the NEXT button below

the two fields.

After clicking on the NEXT button, a window will

pop up in the middle of the screen reminding you that creating a maintenance

profile is a 2-step process: the second step is adding at least one maintenance

type to the profile to create it. Click

on the OK button in the pop-up window:

Fig 2.72 – Pop-up window notifying user that creating a

profile is a 2-step process

After the pop-up window closes, you will notice that the Add/Edit

Profile box in the upper right part of the screen has been replaced with an

Add/Edit Maint. box:

Fig 2.73 – “Add/Edit Maint.” box for adding a maintenance

type to a profile

The Add/Edit Maint. box is where you enter the one

maintenance type you need to create the maintenance profile, since every

maintenance profile needs at least one maintenance type. The first thing you should do is select the

name of the maintenance type you are adding to the maintenance profile by

selecting from the Maintenance Type drop-down box at the top of the Add/Edit

Maint. box. You will only be able

to select from maintenance type names that you have already entered into EZM

Web. For information on how to enter

these maintenance type names, see section 2.1.3 Maintenance Types.

Next, you’ll need to enter the frequency at which the

maintenance type you are entering occurs (see fig 2.74). If you enter the frequency both in days and

logged hours of usage, the maintenance will become due when whichever of the

two comes first.

![]()

Fig 2.74 – Fields where scheduling information for a

maintenance type is entered

Lastly,

you can enter a description of the maintenance type in the Description

field, although this is optional.

Once you

have entered the name for the maintenance type, the frequency at which the

maintenance takes place, and (optionally) the description, click on the SAVE

button at the lower right hand corner of the Add/Edit Maint. box. The equipment maintenance profile will have

been created: you will see the maintenance profile appear in the list of

profiles, and it will have the one maintenance type you specified, which will

be shown to the left of the Add/Edit Maint. box:

![]()

Fig 2.75 – Single maintenance type shown after creation of

maintenance profile

Adding More Maintenance

Types to a Profile

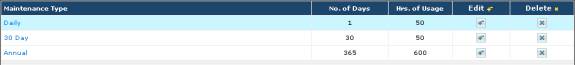

To add more maintenance types to a profile, first look at

the list of maintenance profiles (see fig. 2.70) and find the maintenance

profile to which you want to add one or more additional maintenance types. Click on the name of the maintenance profile

to which you want to add more maintenance types to select it. The list of maintenance types in the profile

you selected will be shown below the list of equipment maintenance profiles:

Fig 2.76 – List of maintenance types for a selected

profile

Now, to add maintenance types to the profile, use the Add

/ Edit Maint. box to the right of the list of maintenance types (this is

shown in fig. 2.74). The first thing

you should do is select the name of the maintenance type you are adding to the

maintenance profile by selecting from the Maintenance Type drop-down box

at the top of the Add/Edit Maint. box.

You will only be able to select from maintenance type names that you

have already entered into EZM Web. For

information on how to enter these maintenance type names, see section 2.1.3 Maintenance Types.

Next, you’ll need to enter the frequency at which the

maintenance type you are entering occurs (see fig 2.74). If you enter the frequency both in days and

logged hours of usage, the maintenance will become due when whichever of the

two comes first. If you are not

scheduling by hours of usage and are only scheduling by number of days, then

you can enter “0” for the hours.

Lastly, you can enter a description of the maintenance

type in the Description field, although this is optional.

Once you have entered the name for the maintenance type,

the frequency at which the maintenance takes place, and (optionally) the

description, click on the SAVE button at the lower right hand corner of

the Add/Edit Maint. box. The new

maintenance type will be added to the maintenance profile and will be displayed

in the list of maintenance types.

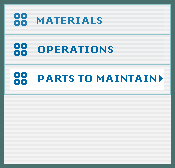

Specifying the Steps to

Take to Complete a Maintenance Type

Every maintenance type you have in a maintenance profile

includes the steps to take to complete the maintenance type. These are referred to as the “operations”.

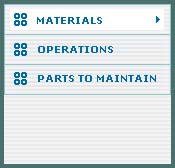

To do this, first select the maintenance type to which you

want to add an operation by clicking on it.

Then look in the lower left corner of the screen for a box that has

three options: MATERIALS, OPERATIONS, and PARTS TO MAINTAIN:

Fig 2.77 – Box with “MATERIALS”, “OPERATIONS”, and “PARTS

TO MAINTAIN” options

Click on OPERATIONS. Once you have clicked there, a list of all of the operations in

the maintenance type will display to the right (or will be empty if you haven’t

entered any operations yet):

Fig 2.78 – List of operations

For each operation in the list, the sequence/step no. is

shown (Sequence No.), the operation name is shown (Operation),

and a detailed description of the operation (Operation Description).

To add a new operation, use the Add/Edit Operations

box to the right to add a new operation to the list:

Fig 2.79 – “Add/Edit Operations” box used to add a new

operation to a maintenance type

First, enter the step no. of the operation: in other

words, if it’s the 1st, 2nd, 4th step,

etc. Do this by clicking in the Sequence

No. box and typing in a number.

Then select the operation you want to add from the Operation drop-down

box. Keep in mind that only the

operations you entered into EZM Web so far are available to be entered

here. (See section 2.1.6 Equipment Maintenance Operations for

how to enter equipment maintenance operations into EZM Web.)

Once you have entered the sequence number and selected the

operation, then click on the SAVE button to add the operation to the

maintenance type. You may add as many

operations as necessary to specify all of the steps needed to complete the

maintenance.

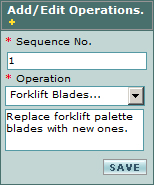

You can also edit an operation that you’ve already

entered: you can change the sequence number, the operation description, or the

operation itself. To do this, locate

the operation in the list which you want to edit and then look to the right of

it until you encounter a ![]() button under the Edit column. Once you click on the edit button, the information about the

operation you’re editing will appear in the Add/Edit Operations box:

button under the Edit column. Once you click on the edit button, the information about the

operation you’re editing will appear in the Add/Edit Operations box:

Fig 2.80 – Editing an operation in the “Add/Edit

Operations” box

In the Add/Edit Operations box, edit any of the

information you wish, and then click on the SAVE button. The operation will be updated with the new

information.

To delete a operation from the maintenance type, locate

the operation in the list and then look to the right of it until you encounter

a ![]() button under the Delete column. Click on the

button under the Delete column. Click on the ![]() button. The operation to

the left of the delete button you clicked will be deleted from the list.

button. The operation to

the left of the delete button you clicked will be deleted from the list.

Specifying the Materials

Used in the Maintenance

When you add materials to a maintenance type, those

materials will be used every time the maintenance is performed. In addition, the materials you add to the

maintenance type will automatically be deducted from your inventory every time

you complete a work order for that maintenance.

To begin adding materials to a maintenance type, first

look in the lower left corner of the screen for a box that has three options: MATERIALS,

OPERATIONS, and PARTS TO MAINTAIN:

Fig 2.81 – Box with “MATERIALS”, “OPERATIONS”, and “PARTS

TO MAINTAIN” options

Click on MATERIALS. Once you have clicked there, a list of all of the materials in

the maintenance type will display to the right (or will be empty if you haven’t

entered any materials yet):

Fig 2.82 – List of materials

For each

material in the list, its unique identification number is shown (Material

No.), the material name is shown (Material Description), and the

quantity used in the maintenance is shown (Qty.).

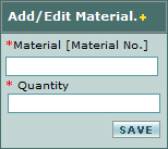

To add a

new material, use the Add/Edit Material box to the right to add a

new material to the list:

Fig 2.83 – “Add/Edit Material” box used to add a new

material to a maintenance type

First, enter the name of the material you want to add Do this by clicking in the Material box

and typing in the name. EZM Web will automatically

generate a drop-down list for materials in your inventory whose name matches

what you have typed so far. When you

see the material you want to add, then click on that material in the drop-down

list. Then enter the quantity of the

material you want to use. Keep in mind

that only the materials you entered into EZM Web so far for equipment

maintenance are available to be entered here.

(See section 2.1.4 Materials

for Equipment Maintenance for how to enter materials for equipment

maintenance into EZM Web.)

Once you have entered the material and the quantity, then

click on the SAVE button to add the material to the maintenance

type. You may add as many materials as

necessary to specify all of the materials needed in the maintenance.

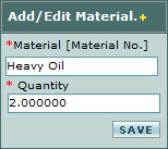

You can also edit an material that you’ve already entered:

you can change both the material and the quantity used. To do this, locate the material in the list

which you want to edit and then look to the right of it until you encounter

a ![]() button under the Edit column. Once you click on the edit button, the information about the

material you’re editing will appear in the Add/Edit Material box:

button under the Edit column. Once you click on the edit button, the information about the

material you’re editing will appear in the Add/Edit Material box:

Fig 2.84 – Editing a material in the “Add/Edit Material”

box

In the Add/Edit Material box, edit any of the

information you wish, and then click on the SAVE button. The material will be updated with the new

information.

To delete

a material from the maintenance type, locate the material in the list and then

look to the right of it until you encounter a

![]() button under the Delete column. Click on the

button under the Delete column. Click on the ![]() button. The material to

the left of the delete button you clicked will be deleted from the list.

button. The material to

the left of the delete button you clicked will be deleted from the list.

Specifying the Replacement Parts Used in the

Maintenance

For each

maintenance type in a maintenance profile, you can specify the parts to be

inspected and possibly replaced in the maintenance. However, unlike materials that are automatically deducted from

inventory when the work order is completed, replacement parts are only deducted

from inventory if the parts actually needed to be replaced during the

maintenance following an inspection. It

is common, for example, to combine a replacement part with an operation that

specifies that the existing part be inspected and replaced if damaged.

To begin

adding replacement parts to a maintenance type, first look in the lower left

corner of the screen for a box that has three options: MATERIALS,

OPERATIONS, and PARTS TO MAINTAIN:

Fig 2.85 - Box with “MATERIALS”, “OPERATIONS”, and “PARTS

TO MAINTAIN” options

Click on PARTS TO MAINTAIN. Once you have clicked there, a list of all

of the replacement parts in the maintenance type will display to the right (or

will be empty if you haven’t entered any parts yet):

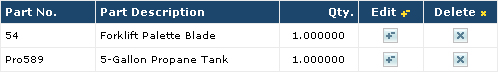

Fig 2.85 – List of Replacement Parts

For each

part in the list, its unique identification number is shown (Part No.),

the material name is shown (Part Description), and the quantity to be

replaced (if necessary) is shown as well (Qty.).

To add a

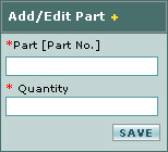

new replacement part, use the Add/Edit Part box to the right to

add a new part to the list:

Fig 2.86 – “Add/Edit Part” box used to add a new

replacement part to a maintenance type

First, enter the name of the replacement part you want to

add. Do this by clicking in the Part

box and typing in the name. EZM Web

will automatically generate a drop-down list for replacement parts in your

inventory whose name matches what you have typed so far. When you see the part you want to add, then

click on that part in the drop-down list.

Then enter the quantity of the part you would need to replace in the

instance of a part failure or failed inspection. Keep in mind that only the parts you entered into EZM Web so far

for equipment maintenance are available to be entered here. (See section 2.1.5 Parts for Equipment Maintenance for

how to enter parts for equipment maintenance into EZM Web.)

Once you have entered the part and the quantity, then

click on the SAVE button to add the part to the maintenance type. You may add as many replacement parts as

necessary to specify all of the parts that need to be inspected and/or replaced

during the maintenance.

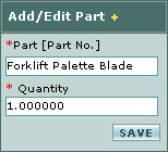

You can also edit a replacement part that you’ve already

entered: you can change both the part and the quantity. To do this, locate the part in the list

which you want to edit and then look to the right of it until you encounter

a ![]() button under the Edit column. Once you click on the edit button, the information about the

material you’re editing will appear in the Add/Edit Part box:

button under the Edit column. Once you click on the edit button, the information about the

material you’re editing will appear in the Add/Edit Part box:

Fig 2.87 – Editing a replacement part in the “Add/Edit

Part” box

In the Add/Edit Part box, edit any of the

information you wish, and then click on the SAVE button. The part will be updated with the new

information.

To delete

a replacement part from the maintenance type, locate the part in the list and

then look to the right of it until you encounter a ![]() button under the Delete column. Click on the

button under the Delete column. Click on the ![]() button. The part to the

left of the delete button you clicked will be deleted from the list.

button. The part to the

left of the delete button you clicked will be deleted from the list.

Reports Available on the Equipment Maintenance

Profile Screen

There are

four reports that you can print from the equipment maintenance profile screen:

·

A report that shows all of the equipment maintenance

profiles that have been entered into EZM Web so far.

·

A report that shows all of the materials in all of your

equipment maintenance profiles.

·

A report that shows all of the operations in all of your

equipment maintenance profiles.

·

A report that shows all of the replacement parts in all of

your equipment maintenance profiles.

To print

any of these reports, first locate the Reports box at the lower-right

corner of the screen:

Fig 2.88 – The “Reports” box showing reports that can be

printed

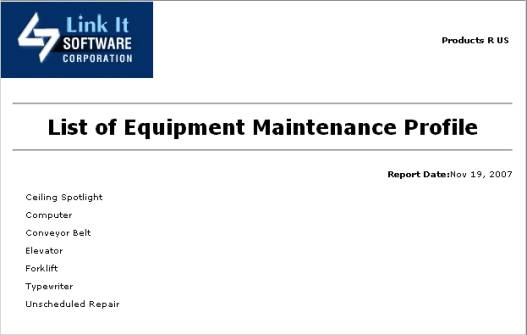

Then click on one of the small circles next to Profile

List, Material, Operation, or Part to select the

report you want to print, and then click on the PRINT button. For example, here is the report that

displays all of the equipment maintenance profiles currently entered into EZM

Web:

Fig 2.89 – Report showing list of all equipment

maintenance profiles