Contents:

- 3.5: Work Orders for Vehicle Maintenance

- 3.5.1: Viewing Vehicle Maintenance

Events

- 3.5.2: Creating Vehicle Work Orders

- 3.5.3: Editing and Closing Work Orders

- 3.5.4: Assigning Work Orders

- 3.5.5: Using the Vehicle Maintenance

Calendar

- 3.5.6: Using the Advanced Search

Feature

3.5 Work Orders for Vehicle

Maintenance

|

|

EZM Web allows you to issue

vehicle work orders for both routine and emergency maintenance and view

maintenance events for vehicles sorted either by vehicle, by the date on which

they are due, or by the usage at which they are due. The main part of EZM Web from which you issue vehicle work orders

is accessed by clicking on Service Due under the Vehicle Service drop-down

list on the left side of the screen:

![]()

3_104: Fig 3.136 – “Service Due” link

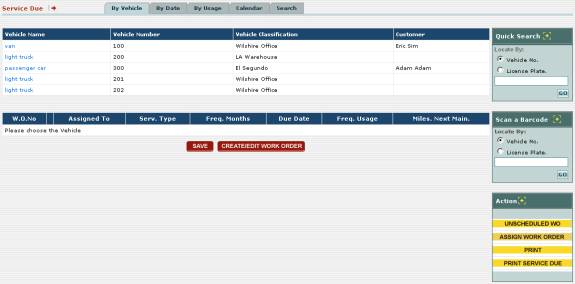

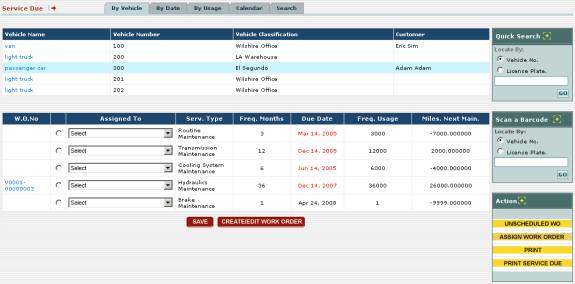

After you click on Service

Due, you will be taken to the following screen, where you will see a list

of all of the vehicles you’ve entered into EZM Web so far:

3_105: Fig 3.137 – “Service Due” section of EZM Web

This screen shows a list of all of the vehicles you’ve

entered so far because here you can view maintenance events sorted by

vehicle. Here you can select a vehicle

and view the maintenance events for it and, if you wish, create a work order

for a scheduled maintenance event or for an unscheduled emergency

maintenance. In the following sections

this guide will explain how to view maintenance events for vehicles and how to

create work orders for vehicle maintenance.

3.5.1 Viewing Vehicle Maintenance Events

As mentioned earlier in this guide, there are three ways

to view maintenance events for vehicles: sorted either by vehicle, by the date

on which it’s due, or by the usage at which it is due.

Viewing Vehicle

Maintenance Events Sorted by Vehicle

To view vehicle maintenance

events sorted by vehicle, first you need to go to the section of EZM Web where

you view vehicle maintenance (see section 3.5

Work Orders for Vehicle Maintenance for how to get here). Click on the By Vehicle tab (the

leftmost tab) at the top of the screen.

This will take you to the following screen where you can see the

maintenance events sorted by vehicle:

3_105: Fig 3.138 – Screen where you view vehicle

maintenance events sorted by vehicle

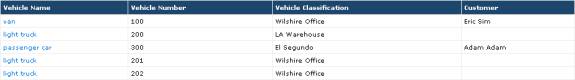

Notice that there is a list of

all the vehicles you have entered into EZM Web so far:

3_106: Fig 3.139 – List of vehicles currently entered into

EZM Web

To see the list of maintenance

events for a vehicle, you must first select a vehicle by clicking on its

vehicle name in the left most column of this list called Vehicle Name. The vehicle name is shown in blue text. Use the vehicle number in the Vehicle

Number column to identify which vehicle you are selecting; the vehicle

number uniquely identifies each vehicle within EZM Web. Once you have selected a vehicle by clicking

on its vehicle name, all of the maintenance events for that vehicle will be

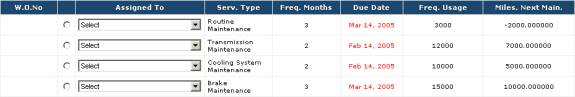

shown below:

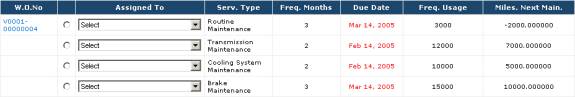

3_107: Fig 3.140 – List of maintenance events for a

particular vehicle

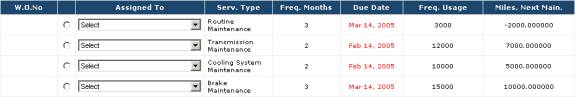

For each maintenance event, you

can see the following information:

o

W.O.No: If a work order has been

created for a maintenance event, the work order number will show in this

column. Each work order number uniquely

identifies a particular work order.

o

Assigned To: If a work order has been

created, this is the person to whom the work order is assigned. Later, in section 3.5.4 Assigning Work Orders this guide will show how to assign work orders.

o

Serv. Type: This is the type of

maintenance which is maintenance event is for.

Each service type prescribes a given set of services to be performed on

at a frequency (in months and/or in usage miles) specified by the user. Each service in turn specifies a set of

operations required to complete the service as well as the materials and

replacement parts needed. See sections 3.1.3 Service Types and 3.1.8 Vehicle Service Profiles for

more information.

o

Freq. Months: This is the frequency at

which this maintenance event is performed, in months.

o

Due Date: This is the date on which the

maintenance event is due.

o

Freq. Usage: This is the frequency at

which this maintenance event is performed, in usage miles.

o

Miles Next Main.: This is

the amount of usage miles remaining before the maintenance event will become

due.

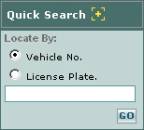

You can also jump to the

maintenance events for a specific vehicle if you know its unique vehicle number

or its license plate number, or if that vehicle has a barcode which you have

printed for it (see section 3.4 Printing Vehicle Barcode Labels for

more information on how to print vehicle barcodes).

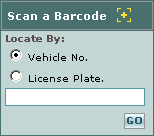

On the right side of the screen

is a Quick Search box which you can use to jump to the maintenance for a

specific vehicle if you know its vehicle number or its license plate number:

3_108: Fig 3.141 – “Quick Search” box to locate vehicle

maintenance by Vehicle No. or License Plate.

To search by vehicle number or

manufacturer serial number, first click on one of the circles labeled Vehicle

No. or License Plate. to search by vehicle number or license place

number respectively. Then, depending on

what you just selected, type the vehicle number or license plate number of the

vehicle in the box immediately below and click on the small GO

button. All of the maintenance events

for the vehicle which you specified will be shown.

You can also jump to the

maintenance events for a specific vehicle by scanning a barcode. This is done using the Scan a Barcode

box which is also on the right side of the screen:

3_109: Fig 3.142 – “Scan a Barcode” box used to locate

maintenance events for a vehicle

To search by scanning a barcode,

first you will need to select whether the barcode you are scanning contains a

vehicle number or a license plate number: to do this, click on one of the

circles labeled Vehicle No. or License Plate.. Then click in the box immediately below and

swipe the barcode with your scanner, and then click on the small GO

button. All of the maintenance events

for the vehicle which you scanned will be shown.

3.5.2 Creating Vehicle Work Orders

EZM Web allows you to create

work orders for both routine scheduled maintenance events and for unscheduled

repairs, such as in the event of an unexpected vehicle breakdown. First, we will describe how to create a work

order for a routine scheduled maintenance event.

Creating

Scheduled Vehicle Work Orders

To create a work order for a

routine scheduled maintenance event, first you need to view maintenance events

either by vehicle, by date, or by usage.

In this discussion, we will show how to create a scheduled work order while

viewing maintenance by vehicle. (See

section 3.5.1 Viewing Vehicle

Maintenance Events for how to view maintenance sorted by vehicle, as

well as by date or by usage.)

3_105: Fig 3.143 – Viewing maintenance events by vehicle

Once you are at the screen where

you view maintenance events by vehicle, select a vehicle by clicking on its

vehicle name in the left most column of this list called Vehicle Name. The vehicle name is shown in blue text. Use the vehicle number in the Vehicle

Number column to identify which vehicle you are selecting; the vehicle

number uniquely identifies each vehicle within EZM Web. Once you have selected a vehicle by clicking

on its vehicle name, all of the maintenance events for that vehicle will be

shown below:

3_107: Fig 3.144 – List of maintenance events for a

particular vehicle

Any maintenance events for which

you have already created a work order have the work order number listed in the W.O.No

column—which is the leftmost column—in the list of maintenance events. Conversely, a maintenance event for which a

work order has not been created will not have a work order number. To create a new work order for a maintenance

event, first select the maintenance event for which you want to create a work

order by clicking in one of the circles in the column immediately to the right

of the W.O.No column. Then click

on the CREATE/EDIT WORK ORDER button, which will open up the following

screen:

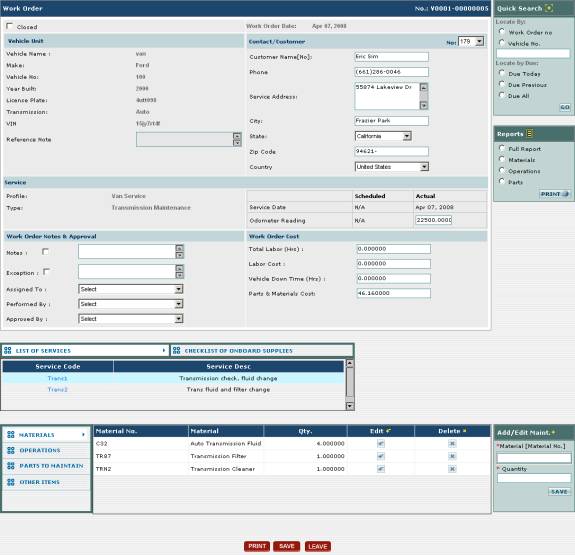

3_110: Fig 3.145 – List of maintenance events for a

particular vehicle

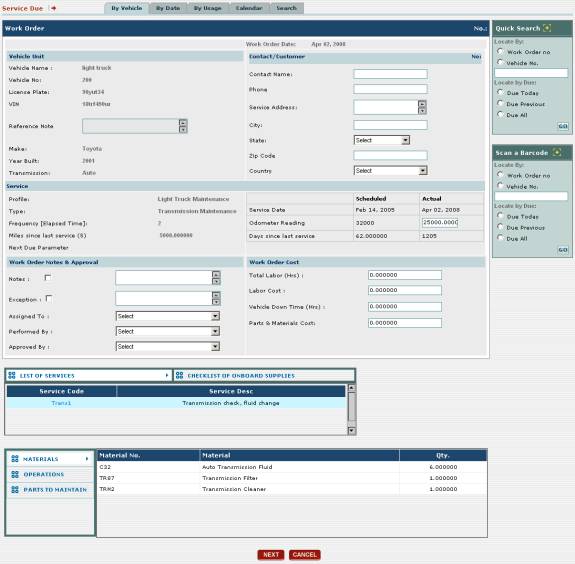

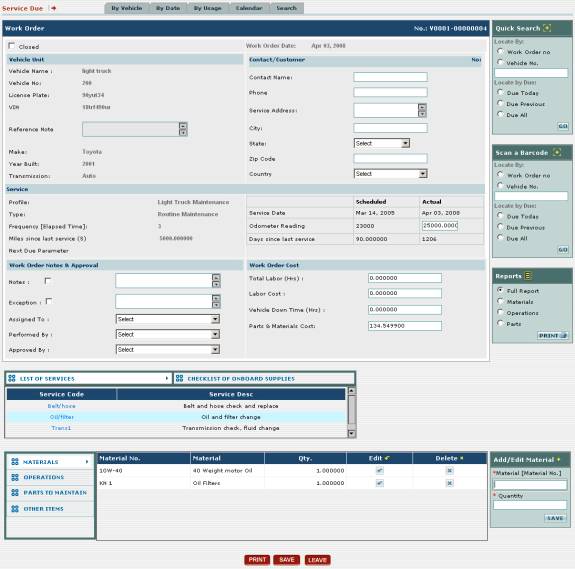

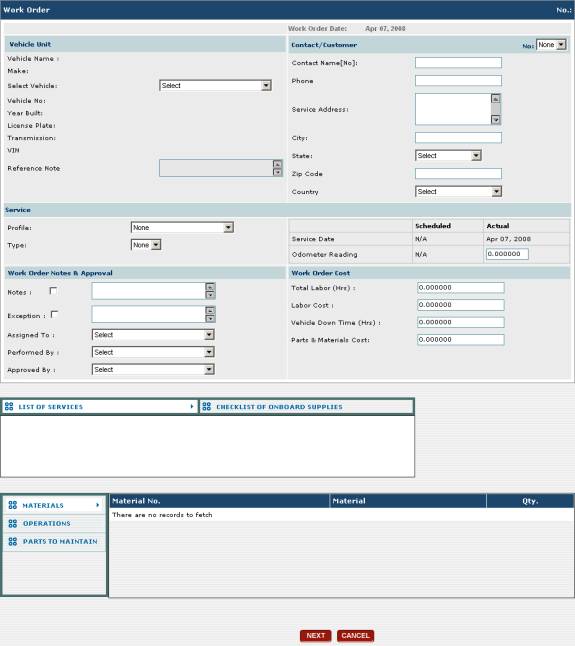

This is the screen at which you

create a work order. As you can see,

there are many data items on this screen, some of which are automatically

filled in and some of which you have to provide data for. The work order screen is divided into

several sections, which we will cover in order, going from top to bottom.

The first data area on the work

order screen is the Vehicle Unit data area. This data area displays some basic properties of the vehicle for

which you are creating the work order and are all filled in automatically with

the information you provided when you entered the vehicle into EZM Web:

o

Vehicle Name: Here the vehicle name,

which specifies the type of vehicle, of the vehicle for which you are creating

the work order is displayed. See

section 3.1.1 Vehicle Names for more information on vehicle names.

o

Vehicle No: Here the vehicle number

which you have chosen to uniquely identify the vehicle within EZM Web is

displayed. The vehicle number may or

may not correspond with your own internal cataloguing system you use for

identifying your vehicles.

o

License Plate: Here the license plate

for the vehicle for which you are creating a work order is displayed.

o

VIN: Here the vehicle’s VIN number

is displayed.

o

Reference Note: Here

any extra information that doesn’t fall under any of the other data areas is

noted. The vehicle reference notes are

entered when the vehicle is created in EZM Web. See section 3.2.2

Entering a New Vehicle or 3.2.3

Editing a Vehicle for further information on entering notes on vehicles

or other data items.

o

Model: This is the make of the

vehicle.

o

Year Built: This is the year in

which the vehicle was built.

o

Transmission: This is the type of

transmission the vehicle has.

The next data area on the work

order is the Contact / Customer area.

If the vehicle for which you are creating the work order belongs to a

customer for whom you are performing maintenance, the name of the customer will

automatically be filled in here as well as their phone number, address, city,

state, zip code, and the country in which they are located.

The next data area on the work

order screen is the Service data area.

This shows some properties about what kind of maintenance the vehicle

requires and what particular maintenance is being performed is the work order

you are creating:

o

Profile: This is the service profile

for the vehicle for which you are creating the work order. The service profile is a complete description

of the maintenance for a vehicle. See

section 3.1.8 Vehicle Service Profiles

for full information on service profiles.

o

Type: This is the type of

maintenance that is being performed.

o

Frequency [Elapsed Time]: This is

the frequency at which this service type is performed, in months.

o

Miles since last service (S): This is

the amount of usage miles that have been logged since the last time the vehicle

received the service type which this work order is for.

To the right of these four data

items there is a small chart showing the difference between when the

maintenance was scheduled and when the maintenance is actually being

performed. The Service Date, Odometer

Reading, and Days since last service where the vehicle is actually

scheduled for maintenance are all shown along with the actual points when the

work is being done. The actual Odometer

Reading is simply filled in with the current mileage for the vehicle as

recorded in EZM Web. If the actual

mileage for the vehicle differs from what is shown here (in other words, there

are miles that have not been logged yet), you can click in the Actual

Odometer Reading box and type in the current mileage. A usage log entry for that vehicle will

automatically be created that is the difference between what has already been

recorded in EZM Web and what you entered into the Actual Odometer Reading

box.

The next data area on the work

order screen is Work Order Notes & Approval:

o

Notes: This is where you enter any

additional notes about this maintenance.

The checkbox to the left of the box where you type the notes will

automatically be checked to indicate that you have entered some notes.

o

Exception: This is where you

indicate that there are changes made to what is usually prescribed in this

maintenance. The checkbox next to the

field in which you type exceptions will be automatically checked to indicate

that there are exceptions for this work order.

o

Assigned To: This is where you select

the person to whom the responsibility for performing this work is

assigned. Select the person to whom you

want to assign the work from the drop-down list.

o

Performed By: This is where the person

who actually performs the work is selected.

Select the person who is actually performing the work from the drop-down

list.

o

Approved By: This is

where you indicate the person who reviewed the work upon completion. Select the person who reviewed the work from

the drop-down list.

The next data area on the work

order screen is Work Order Cost.

This is where you enter the costs associated with performing the work

prescribed in the work order:

o

Total Labor (Hrs): This is

the total amount of hours spent performing the labor prescribed in the work

order.

o

Labor Cost: This is the total cost

for the labor.

o

Vehicle Down Time (Hrs): This is

the total amount of hours that the vehicle was down for repairs.

o

Parts & Materials Cost: This is

the total cost of the parts and materials used in the maintenance. The amount in this field is automatically

calculated from the materials used in the maintenance and the parts you have

chosen to replace.

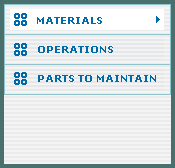

Lastly, at the bottom of the

work order screen, you can view the operations performed and the materials and

replacement parts used in each service included in the work order as well as a

checklist of onboard supplied needed in the work order. First, to see what operations, materials,

and parts are included in a service, you must select the service from the LIST

OF SERVICES:

3_111: Fig 3.146 – List of services included in the work order

In the list of services, the Service

Code for each service is listed along with a short description of the

service under the Service Desc column.

To see the operations, materials, and parts for a service, click on that

service’s code, shown in blue text, under the Service Code column. Once you have clicked on the service code,

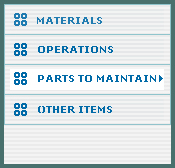

then you can view the operations, materials, and parts for that service. Look in the lower left corner of the screen

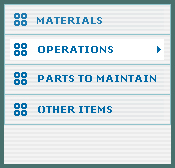

for a box that has three options: MATERIALS, OPERATIONS, and PARTS

TO MAINTAIN:

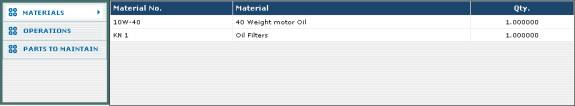

3_112: Fig 3.147 – Box where you select whether you wan to

view materials, operations, or parts in a service

Click on MATERIALS, OPERATIONS,

or PARTS TO MAINTAIN in the box at the bottom left corner of the work

order screen. Depending on what you

clicked, the materials, operations, and parts to maintain will then show to the

right of that box:

3_113: Fig 3.148 – Viewing the materials included in a

service

You can also view the checklist

of onboard supplies by clicking on CHECKLIST OF ONBOARD SUPPLIES above

the list of services.

Once you save the work order,

you can edit the materials, operations, and parts to maintain for each service

included in the work order. Once you

have reviewed all of the information in the work order and want to save it,

click on the NEXT button at the bottom of the work order screen to save

the work order, or you can click on the CANCEL button if you have

changed your mind and no longer want to create the work order. After clicking on the SAVE & NEXT

button, the work order will be created and you will see the following screen:

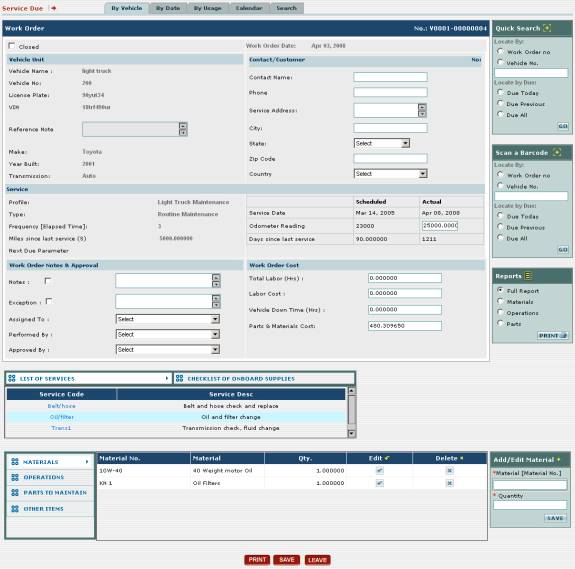

3_114: Fig 3.149 – Work order screen after saving work

order

This screen is similar to the one earlier, except that you

can do a few more things: you can print the work order, you can also change the

materials, operations, and parts to maintain in each service, and you can also

add other ad hoc items you want to use in the maintenance.

There are two ways you can print

the work order: you can click on the PRINT button at the bottom of the

screen, or you can use the Reports box at the right side of the screen:

3_115: Fig 3.150 – Box where you select what type of work

order you want to print

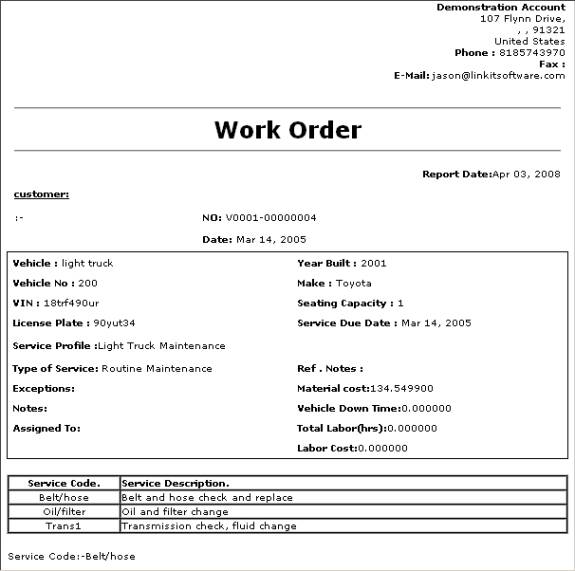

To print the full work order using the Reports box,

begin by clicking on the circle called Full Report to select it. Then click on the small PRINT button

in the lower right corner of the box.

After selecting your printer, the work order will print:

3_116: Fig 3.151 – Work order printout

When you select Full Report, the work order that

prints out contains all of the Materials, Operations, and Parts, and

other items included in each service in the work order You can also use the Reports box to

print a work order that only contains the Materials, Operations, or Parts

required in each service in the work order.

To do this, select one of the circles called Materials, Operations,

or Parts in the Reports box, and then click on the PRINT

button at the lower right.

Lastly, you can choose the materials, operations, parts to

maintain, and other items that are to be included in each service in the work

order. First, to change what

operations, materials, and parts are included in a service, you must select the

service from the LIST OF SERVICES:

3_188: Fig 3.152 – List of services

To change the operations, materials, and parts for a

service, click on that service’s code, shown in blue text, under the Service

Code column. Once you have clicked

on the service code, then you can view and change the operations, materials,

and parts for that service. Look in the

lower left corner of the screen for a box that has three options: MATERIALS,

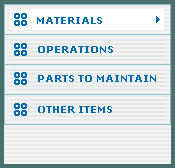

OPERATIONS, PARTS TO MAINTAIN and OTHER ITEMS:

3_117: Fig 3.153 – Box where you select whether you want

to edit materials, operations, parts, or other items

Click on MATERIALS. Once you have clicked there, a list of all of the materials in

the service you selected will display to the right (or will be empty if you

haven’t entered any materials yet):

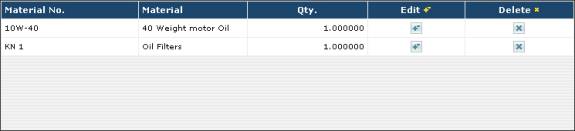

3_118: Fig 3.153 – List of materials

For each material in the list,

its unique identification number is shown (Material No.), the material

name is shown (Material), and the quantity used in the maintenance is

shown (Qty.). To add a new

material, use the Add/Edit Material box to the right to add a new

material to the list:

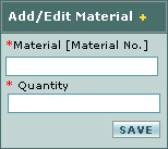

3_119: Fig 3.154 – “Add/Edit Material” box used to add a

new material to a service

First, enter the name of the material you want to add. Do

this by clicking in the Material box and typing in the name. EZM Web will automatically generate a

drop-down list for materials in your inventory whose name matches what you have

typed so far. When you see the material

you want to add, then click on that material in the drop-down list. Then enter the quantity of the material you

want to use. Keep in mind that only the

materials you entered into EZM Web so far for vehicle maintenance are available

to be entered here. (See section 3.1.4 Materials for Vehicle Maintenance for

how to enter materials for vehicle maintenance into EZM Web.) Once you have entered the material and the

quantity, then click on the SAVE button to add the material to the work

order.

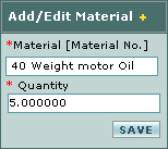

You can also edit a material that you’ve already entered:

you can change both the material and the quantity used. To do this, locate the material in the list

which you want to edit and then look to the right of it until you encounter

a ![]() button under the Edit column. Once you click on the edit button, the information about the

material you’re editing will appear in the Add/Edit Material box:

button under the Edit column. Once you click on the edit button, the information about the

material you’re editing will appear in the Add/Edit Material box:

3_120: Fig 3.155 – Editing a material in the “Add/Edit

Material” box

In the Add/Edit Material box, edit any of the

information you wish, and then click on the SAVE button. The material will be updated with the new

information.

To delete a material from the

service, locate the material in the list and then look to the right of it until

you encounter a ![]() button under the Delete column. Click on the

button under the Delete column. Click on the ![]() button. The material to

the left of the delete button you clicked will be deleted from the list.

button. The material to

the left of the delete button you clicked will be deleted from the list.

You can also change the operations performed in the

service. To do this, first look in the

lower left corner of the screen for the box with four options: MATERIALS,

OPERATIONS, PARTS TO MAINTAIN, and OTHER ITEMS:

3_121: Fig 3.156 – Box where you select whether you want

to edit materials, operations, parts, or other items

Click on OPERATIONS. Once you have clicked there, a list of all of the operations in

the service will display to the right (or will be empty if you haven’t entered

any operations yet):

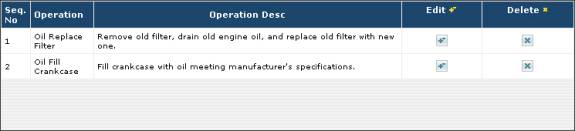

3_122: Fig 3.157 – List of operations

For each operation in the list, the sequence/step no. is

shown (Seq. No.), the operation name is shown (Operation), and a

detailed description of the operation (Operation Desc).

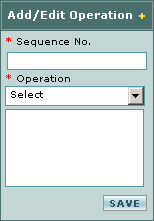

To add a new operation, use the Add/Edit Operation

box to the right to add a new operation to the list:

3_123: Fig 3.158 – “Add/Edit Operations” box used to add a

new operation to a service

First, enter the step no. of the operation: in other words,

if it’s the 1st, 2nd, 4th step, etc. Do this by clicking in the Sequence No.

box and typing in a number. Then select

the operation you want to add from the Operation drop-down box. Keep in mind that only the operations you

entered into EZM Web so far for vehicle maintenance are available to be entered

here. (See section 3.1.7 Vehicle Maintenance Operations for

how to enter vehicle maintenance operations into EZM Web.) Once you have entered the sequence number and

selected the operation, then click on the SAVE button to add the

operation to the service.

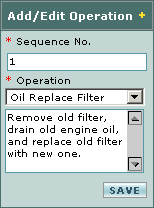

You can also edit an operation that you’ve already

entered: you can change the sequence number, the operation description, or the

operation itself. To do this, locate

the operation in the list which you want to edit and then look to the right of

it until you encounter a ![]() button under the Edit column. Once you click on the edit button, the information about the

operation you’re editing will appear in the Add/Edit Operations box:

button under the Edit column. Once you click on the edit button, the information about the

operation you’re editing will appear in the Add/Edit Operations box:

3_124: Fig 3.159 – Editing an operation in the “Add/Edit

Operations” box

In the Add/Edit Operations box, edit any of the

information you wish, and then click on the SAVE button. The operation will be updated with the new

information.

To delete a operation from the service, locate the

operation in the list and then look to the right of it until you encounter

a ![]() button under the Delete column. Click on the

button under the Delete column. Click on the ![]() button. The operation to

the left of the delete button you clicked will be deleted from the list.

button. The operation to

the left of the delete button you clicked will be deleted from the list.

You can also change the

replacement parts used in the service.

Unlike materials that are automatically deducted from inventory when the

work order is completed, replacement parts are only deducted from inventory if

the parts actually needed to be replaced during the maintenance following an

inspection. It is common in a service,

for example, to combine a replacement part with an operation that specifies

that the existing part be inspected and replaced if damaged.

To change the replacement parts

in the service, first look in the lower left corner of the screen for a box

that has four options: MATERIALS, OPERATIONS, PARTS TO

MAINTAIN, and OTHER ITEMS:

3_125: Fig 3.160 - Box where you select whether you want

to edit materials, operations, parts, or other items

Click on PARTS TO MAINTAIN. Once you have clicked there, a list of all

of the replacement parts in the service will display to the right (or will be

empty if you haven’t entered any parts yet):

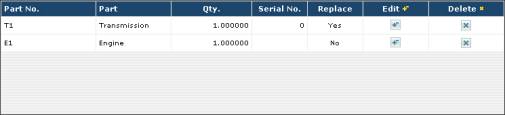

3_126: Fig 3.161 – List of Replacement Parts

For each part in the list, its

unique identification number is shown (Part No.), the part name is shown

(Part), the quantity to be replaced (if necessary) is shown (Qty.),

and the serial number is shown (Serial No.).

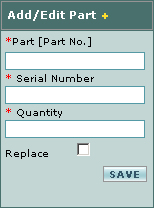

To add a new replacement part,

use the Add/Edit Part box to the right to add a new part to the

list:

3_127: Fig 3.162 – “Add/Edit Part” box used to add a new

replacement part to a service

First, enter the name of the replacement part you want to

add. Do this by clicking in the Part

box and typing in the name. EZM Web

will automatically generate a drop-down list for replacement parts in your

inventory whose name matches what you have typed so far. When you see the part you want to add, then

click on that part in the drop-down list.

Then enter the quantity of the part you would need to replace in the

instance of a part failure or failed inspection. Then enter the serial number of the part you are inspecting and

possibly replacing in the Serial Number box. Keep in mind that only the parts you entered into EZM Web so far

for vehicle maintenance are available to be entered here. (See section 3.1.5 Replacement Parts for Vehicle

Maintenance for how to enter parts for vehicle maintenance into EZM

Web.) Once you have entered the part,

the serial number, and the quantity, then click on the SAVE button to

add the part to the service.

You can also edit a replacement part that you’ve already

entered: you can change both the part and the quantity. To do this, locate the part in the list

which you want to edit and then look to the right of it until you encounter

a ![]() button under the Edit column. Once you click on the edit button, the information about the

material you’re editing will appear in the Add/Edit Part box:

button under the Edit column. Once you click on the edit button, the information about the

material you’re editing will appear in the Add/Edit Part box:

3_128: Fig 3.163 – Editing a replacement part in the

“Add/Edit Part” box

In the Add/Edit Part box, edit any of the

information you wish, and then click on the SAVE button. The part will be updated with the new

information.

To delete a part from the

service, locate the part in the list and then look to the right of it until you

encounter a ![]() button under the Delete column. Click on the

button under the Delete column. Click on the ![]() button. The part to the

left of the delete button you clicked will be deleted from the list.

button. The part to the

left of the delete button you clicked will be deleted from the list.

Lastly, you can add other ad hoc

items to the service that aren’t already listed in your inventory. To do this, first look in the lower left

corner of the screen for the box that has four options: MATERIALS,

OPERATIONS, PARTS TO MAINTAIN, and OTHER ITEMS:

3_129: Fig 3.164 - Box where you select whether you want

to edit materials, operations, parts, or other items

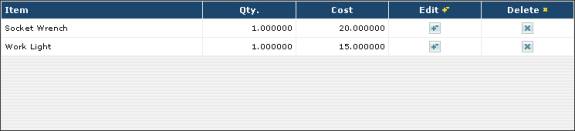

Click on OTHER ITEMS. Once you have clicked there, a list of all

of the other items in the work order will display to the right (or will be

empty if you haven’t entered anything yet):

3_130: Fig 3.165 – List of other items

For each item in the list, the

name of the item is shown (Item), the quantity is shown (Qty.),

and the cost of the item is shown (Cost).

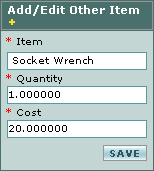

To add a new other item, use the

Add/Edit Other Item box to the right to add a new item to the

list:

3_131: Fig 3.166 – Adding an other item to the work order

First, enter the name of the

item you want to add in the Item box.

Then enter the quantity of that item you are going to use in the Quantity

field. Then enter the total cost of the

item or items into the Cost field; the cost which you enter here will

automatically be added to the Parts & Materials Cost on the work

order. Once you have entered all of

this information, click on the SAVE button to the lower right to add the

item to the work order.

You can also edit an item that

you’ve already entered: you can change the name of the item, the quantity, and

the cost. To do this, locate the item

in the list which you want to edit and then look to the right of it until you

encounter a ![]() button under the Edit column. Once you click on the edit button, the information about the item

you’re editing will appear in the Add/Edit Other Item box:

button under the Edit column. Once you click on the edit button, the information about the item

you’re editing will appear in the Add/Edit Other Item box:

3_132: Fig 3.167 – Editing an other item

In the Add/Edit Other Item

box, edit any of the information you wish, and then click on the SAVE

button. The item will be updated with

the new information.

To delete an item from the

service, locate the item in the list and then look to the right of it until you

encounter a ![]() button under the Delete column. Click on the

button under the Delete column. Click on the ![]() button. The item to the

left of the delete button you clicked will be deleted from the list.

button. The item to the

left of the delete button you clicked will be deleted from the list.

Once you have finished entering

all of the information in the work order, click on the SAVE button at

the bottom of the screen to save it.

Creating

Unscheduled Vehicle Work Orders

Creating unscheduled work orders

for vehicle maintenance In EZM Web is similar to creating scheduled work

orders. To create a work order for an

unscheduled maintenance event for a vehicle, first you need to view vehicle

maintenance events either by vehicle, by date, or by usage. In this discussion, we will show how to

create an unscheduled work order while viewing maintenance by vehicle. (See section 3.5.1 Viewing Vehicle Maintenance Events

for how to view maintenance by vehicle, as well as by date or by usage.)

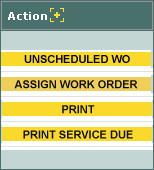

Once you are at the screen where

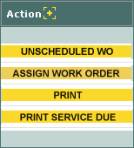

you view maintenance events by vehicle, notice that there is an UNSCHEDULED

WO button at the lower right corner of the screen:

3_133: Fig 3.168 – Editing an other item

Click on the UNSCHEDULED WO

button. You will be taken to the

following screen:

3_134: Fig 3.169 – Screen at which you create an unscheduled

work order

This screen is very similar to

the one at which you create a scheduled work order. The two main differences are that:

1.

You need to select the vehicle for which you are creating

the unscheduled work order here.

2.

You need to select the service profile and service type in

order to specify what kind of maintenance you want to perform.

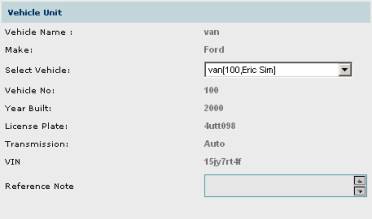

To select the vehicle for which

you want to create the work order use the Select Vehicle drop-down

selection box at the upper left corner of the screen. Once you select the vehicle, all of the details for it will be

automatically filled in:

3_135: Fig 3.170 – Vehicle information on unscheduled work

order screen

If you are maintaining the

vehicle you selected for a customer, that customer’s details will automatically

be shown in the Contact / Customer data area to the right.

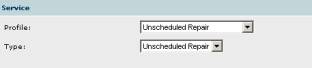

After selecting the vehicle for

which you are creating the unscheduled work order, then you need to select the

type of maintenance you want to perform using the Profile and Type

drop-down selection boxes:

3_136: Fig 3.171 – Selecting maintenance profile and

service type

You can select whichever service

profile and service type which has the maintenance you want to perform. (See sections 3.1.3 Service Types and 3.1.7 Vehicle

Service Profiles). In many

cases, however, there is no existing service profile and service type that

contains the maintenance that addresses the particular breakdown you’ve

experienced. Because of this, you may

want to create a “blank” service profile, service type, and service with no

materials, operations, or replacement parts in it; you would typically call all

three of these something like “Unscheduled Repair” (as shown in figure 3.71 above).

This “blank” service profile, service type and service are then selected

when you want to create an unscheduled work order. You would then add any materials, operations, and replacement

parts to the “Unscheduled Repair” service which you need at the time of the

creation of the work order.

After you have selected the

vehicle and the type of maintenance you want to perform, then click on the NEXT

button at the bottom of the screen, or click on the CANCEL button if you

have changed your mind and no longer want to create the unscheduled work

order. After clicking the NEXT

button, the work order will be saved, and you will be taken to the following

screen:

3_137: Fig 3.172 – Work order screen (changing materials,

parts, operations, and other items for each service)

Just as when you create a

scheduled work order, at this screen you can change the materials, operations,

and replacement parts as well as add other ad hoc items to the work order. If you chose a “blank” service profile and

service type that doesn’t contain any materials, operations, or replacement

parts, then you can add them here. You

may also use the PRINT button and Reports box at the right side

of the screen to print the work order.

Click on the SAVE button at the bottom of the screen to save the

work order.

3.5.3 Editing and Closing

Vehicle Work Orders

Once you have created a vehicle

work order in EZM Web, you may want to make some changes to it. Additionally, you will want to close it when

the work has been completed. In this

section, we will demonstrate how to both edit a vehicle work order and close

it.

Editing

a Vehicle Work Order

To edit a vehicle work order,

first you need to view maintenance events either by vehicle, by date, or by

usage. In this discussion, we will show

how to edit a work order while viewing maintenance by vehicle. (See section 3.5.1 Viewing Vehicle Maintenance Events

for how to view maintenance by vehicle, as well as by date or by usage.)

3_138: Fig 3.173 – Viewing Maintenance Due by Vehicle

As explained in section 3.5.1 Viewing Vehicle Maintenance Events,

you view the maintenance events for each vehicle by clicking on that vehicle in

the list. Then a list of all of the

maintenance events for the vehicle you selected will appear below:

3_139: Fig 3.174 – List of maintenance events for a

vehicle

Each maintenance event for which

a work order has been created has a work order number in the W.O.No

column. If no work order has been

created for a maintenance event, no work order number is shown for it.

To edit an existing work order,

first locate that work order in the list of maintenance events. Then look immediately to the right of the W.O.No

column for a column that contains small circles. Click on the circle that corresponds to the work order you want

to edit, and then click on the CREATE/EDIT WORK ORDER button below the

list of maintenance events. After

clicking on the CREATE/EDIT WORK ORDER button, you will be taken to the

following screen where you can edit the work order:

3_140: Fig 3.175 – Screen where you edit a work order

At this screen you can change

the details of the work order as well as print the work order. See section 3.5.2 Creating Vehicle Work Orders

for information on the meaning of the different data items on this screen as

well as how to change them.

Once you have finished making

your changes to the work order, then click on the SAVE button at the

bottom of the screen. If you have

changed your mind and do not want to make any changes to the work order, then

click on the CANCEL button instead.

Closing

a Work Order

To close a work order, follow

the procedure explained earlier in this section for how to get to the screen

where you edit a work order. Then

locate the Closed checkbox at the upper left corner of the screen:

![]()

3_141: Fig 3.176 – Closed checkbox for closing a work

order

Click in the checkbox to mark

it, and then click on the SAVE button at the bottom of the work order

screen. The work order will then be

closed and go into the vehicle maintenance history for EZM Web. Later, in section 3.6 Vehicle Maintenance History,

we will discuss how to view the vehicle maintenance history.

3.5.4 Assigning Work Orders

EZM Web also has a feature that

lets you assign multiple vehicle work orders and maintenance events to

personnel quickly. You can use this

feature to see all of the maintenance events for vehicles at a glance and

assign multiple work orders to personnel at a single time.

To use this feature, first you

need to view maintenance events either by vehicle, by date, or by usage. (See section 3.5.1 Viewing Vehicle Maintenance Events

for how to view maintenance by vehicle, as well as by date or by usage.) At the lower right part of the screen, you

will see a button called ASSIGN WORK ORDER:

3_142: Fig 3.177 – “ASSIGN WORK ORDER” button

After clicking on the ASSIGN

WORK ORDER button, you will be taken to the following screen, where you’ll

see a list of all of the maintenance events due for vehicles:

3_143: Fig 3.178 – “ASSIGN WORK ORDER” button

All of the maintenance events

for which a work order has already been created have a work order number in the

W.O. NO column. Those

maintenance events with no work order number have not had a work order number

created for them yet. If you assign

somebody to a maintenance event for which no work order has yet been created, a

work order will be automatically created.

To assign the maintenance events

or an existing work orders, use the drop-down boxes on the right side of the

list under the Assigned To column.

You can assign multiple maintenance events or work orders. Once you have made all of the desired

assignments, then click on the ASSIGN button immediately below the

list. To exit this section of EZM Web

without making any assignments, click on the CANCEL button.

3.5.5 Using the Vehicle

Maintenance Calendar

EZM Web also has a feature that

allows you to see what vehicle maintenance events are due on a given day. To use this feature, first you need to view

maintenance events either by vehicle, by date, or by usage. (See section 3.5.1 Viewing Vehicle Maintenance Events

for how to view maintenance by vehicle, as well as by date or by usage.) Then, click on the Calendar tab. You will be taken to the following screen:

3_144: Fig 3.179 – Maintenance calendar with maintenance

events listed for the selected day

At the right of the screen, you

will see a small calendar:

3_145: Fig 3.180 – Maintenance calendar showing selected

date

To see a list of all of the

maintenance events that are due on a particular day, click on that day in the

calendar. To advance the calendar one

month forward or backwards, use the small arrows at the top right and left

corners of the calendar respectively.

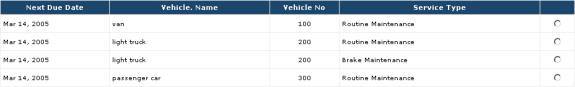

After clicking on a day on the calendar, a list of all of the

maintenance events due on that day will be displayed.

3_146: Fig 3.181 – List of maintenance events for the

selected day

For each maintenance event that

is due, you can see the type of vehicle which the maintenance is for (Vehicle.

Name), the internal control number that uniquely identifies the vehicle for

which the maintenance event is scheduled (Vehicle No), and the type of

the maintenance (Service Type).

To create a work order for one of the maintenance events that is listed

here, click in the circle in the right-most column in the list which

corresponds with the maintenance event to select it. Then click on the CREATE/EDIT WORK ORDER button below the

list. This will open the work order

screen at which you can enter the details about the new work order. (see section 3.5.2 Creating Vehicle Work Orders

for information on how to use this section of EZM Web.)

3.5.6 Using the Advanced Search

Feature

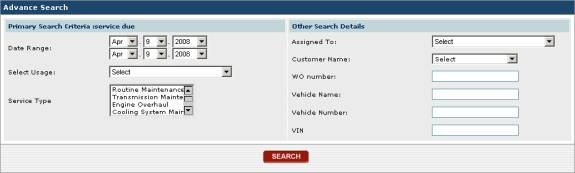

The vehicle service module in

EZM Web includes an advanced search feature that lets you search for maintenance

events based on filtering criteria you enter.

To use this feature, first you need to view maintenance events either by

vehicle, by date, or by usage. (See

section 3.5.1 Viewing Vehicle

Maintenance Events for how to view maintenance by vehicle, as well as

by date or by usage.) Then, click on

the Search tab. You will be

taken to the following screen:

3_147: Fig 3.182 – Advanced search for maintenance events

In this section of EZM Web, you

can enter multiple criteria to search for maintenance events, and any

maintenance events that don’t match the criteria that you entered will be

filtered out leaving only those which match what you entered. The purpose of each data area on the

advanced search form is as follows:

o

Date Range: Here you can select the

date range in which you want to search for maintenance events. Any maintenance events falling outside the

date range you select here will be omitted from your search results. The top set of three boxes let you select

the lower bound of the date range, while the bottom three let you select the

upper bound.

o

Select Usage: Only

maintenance events whose time until due, in usage, which falls within the usage

range you select here will be included in your search results.

o

Service Type: This drop-down box lets

you filter by the type of maintenance.

o

Assigned To: This drop-down box lets

you filter by the person to whom the maintenance is assigned.

o

Customer Name: This drop-down box lets

you filter by the customer for whom you are servicing the vehicle. Only maintenance for vehicles belonging to

the customer you select here will be displayed.

o

WO number: If you want to look for

a particular work order and you know the work order number, type it here.

o

Vehicle Name: This field lets you

filter by the type of vehicle or “vehicle name”. Only the type of vehicle that you enter here will be included in

the search results.

o

Vehicle Number.: If you

want to filter all of the maintenance due for only one specific vehicle and you

know the vehicle number that uniquely identifies it, then you can enter it

here.

o

VIN: If you want to filter all of

the maintenance due for only one specific vehicle and you know the VIN number

that uniquely identifies it, then you can enter it here.

Once you have entered all of

your search criteria, then click on the SEARCH button to display the

list of maintenance events you are searching for.